Current Projects

Model and Simulation of A Hydrofoil

Design for a pneumatic control Box

This ongoing project, conducted in collaboration with a company in the medical field, focuses on the design of a control box for soft actuators that simulate organ-like behavior. The developed system utilizes air pressure and a PID control loop to achieve precise motion of soft structures. The work involves embedded programming with an Arduino Nano, mechanical design, and printed circuit board (PCB) development.

Hydrofoils are high-speed marine vehicles with applications in areas such as survey and exploration missions. This project investigates the underlying physics and mathematical modeling of these systems. The final objective is to design a high-speed autonomous hydrofoil capable of optimizing its trajectory to enhance speed and energy efficiency by harnessing wave energy for extended autonomous operation.

Past Projects

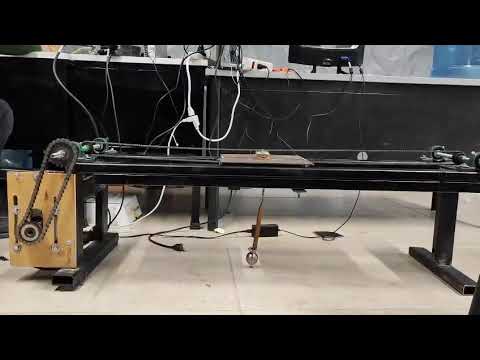

CNC Mill Building

During my internship at Boston Children’s Hospital (BCH), one of my projects involved building a CNC milling machine (Millennium Machine Milo V1.5). The lab’s research focuses on developing wearable devices for disease detection in newborns using Near-Infrared Spectroscopy (NIRS). Previously, we outsourced the manufacturing of custom parts to external companies; however, we decided to acquire the Milo V1.5 CNC kit to perform in-house fabrication.

The CNC system operates with a PID controller and can be accessed directly by connecting to its Wi-Fi network and entering the IP address in a web browser. G-code was generated using Fusion 360. Additionally, we integrated Python-based control to send precise movement commands (1 mm or less) to the CNC’s X and Y axes for experimental applications.

FPGA implementation in a Wearable Device

One of the most complex projects I have worked on involved implementing an FPGA in a device designed to detect diseases in newborns. The most challenging aspect was developing the FPGA application using PetaLinux and configuring data transmission via DMA. Since the system uses Near-Infrared Spectroscopy (NIRS), it required transferring large amounts of data within milliseconds. For instance, we achieved data rates exceeding one million pulses per second. The video below demonstrates how the counter module operates.

The goal was to develop the second generation of an existing device, with the new version designed to significantly reduce the size of the original. The previous model measured approximately 1.5 m × 0.5 m × 0.5 m (H × D × W), while the new version is compact enough to fit in the palm of a hand.

Adaptive Temperature Controller for a laser

In this project, I developed a Model Reference Adaptive Control (MRAC) system using a C2000 microcontroller. As mentioned previously, we were working with several lasers under different operating conditions, making adaptive control an interesting approach to explore and apply. The target temperature was set to 25 °C, and a dummy laser mounted on a heatsink was used for testing the controller. A Peltier module was employed to increase or decrease the temperature of the load as required.

Fluidmaster OEE

During one semester, I worked full-time as a Control Intern Engineer at a company where I contributed to the development of an Overall Equipment Effectiveness (OEE) system for the entire plant. The goal was to publish real-time production data from every process. This task was quite complex, as it required the preparation and standardization of all equipment across the facility. Several technologies were integrated during the project, including vision systems, ABB robots, PLCs, and various sensors.

The video demonstrates the implementation of the OEE system for a group of 52 injection molding machines.

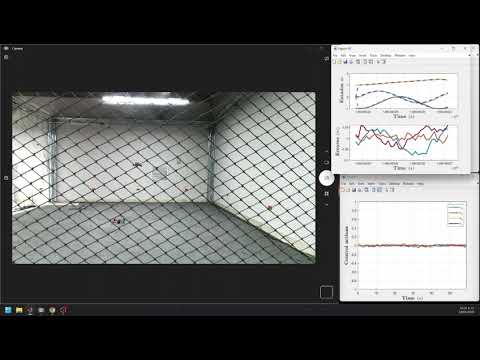

Design and Implementation of a Non-linear Controller for a Drone

A paper was published in which I was involved in the writing, design, simulation, and implementation of the IDA-PBC controller (see acknowledgements).

Implementation and monitoring of IDA-PBC controller

This work marked a milestone in my career and sparked my passion for control systems. In this project, we implemented an Interconnection and Damping Assignment Passivity-Based Control (IDA-PBC) strategy to study the behavior of a nonlinear controller for a drone. We analyzed several scenarios involving two drones—a leader and a follower—under varying loads and disturbances. My responsibilities included developing the control strategy, implementing the controller, and running simulations. Additionally, we compared the performance of the IDA-PBC approach with another nonlinear control method. The OptiTrack system was used to collect motion data and identify the system’s equations of motion through pulse signal analysis.

Gallery